Bozhon Semiconductor promotes the localization process of semiconductor equipment.

Bozhon Semiconductor will make a powerful appearance at the SEMICON China International Semiconductor Exhibition with its highlight new products in 2025, providing solutions for industry customers in areas such as optoelectronic chip, optical device & module packaging, and appearance defect detection of IC chips.

Exhibition Time

Booth Number

01

HIGHLIGHTS

· CesiStar series AOI (Automated Optical Inspection) machines ·

CesiStar series AOI (Automated Optical Inspection) machines

The CesiStar series AOI (Automated Optical Inspection) machines for chip appearance inspection are high-speed, high-precision, fully automated visual inspection devices that utilize optical principles to detect chip defects. They are mainly applied in the research and development as well as the manufacturing of chip packaging. For various packaged chips such as FCBGA, WBBGA, POP, LGA, QFN, and QFP, they provide comprehensive 6-side inspection and 2D/3D measurement.

- Supports chip size range: 2x2-120x120mm

- Comprehensively covers mainstream packaging types such as Lead, Ball, and Leadless

- Supports Tray to Tray and Tray to Reel operations

- Supports a maximum of 4×14 suction nozzles, with an Upstream Per Hour (UPH) of up to 60,000.

- Supports 1×4 sorting suction nozzles.

- High-precision 3D reconstruction, supporting 3D detection at the bottom and top with an accuracy of 5um@3σ

- High-precision 2D detection capability, with the minimum detectable defect size of 20 um

- Integrated 6-Side micro-crack detection capability

- Capable of detecting large-sized chips with a size of 120x120mm

✅ High Usability

- Quick product model changeover

- Efficient human-machine interaction, making it easy to operate

02

HIGHLIGHTS

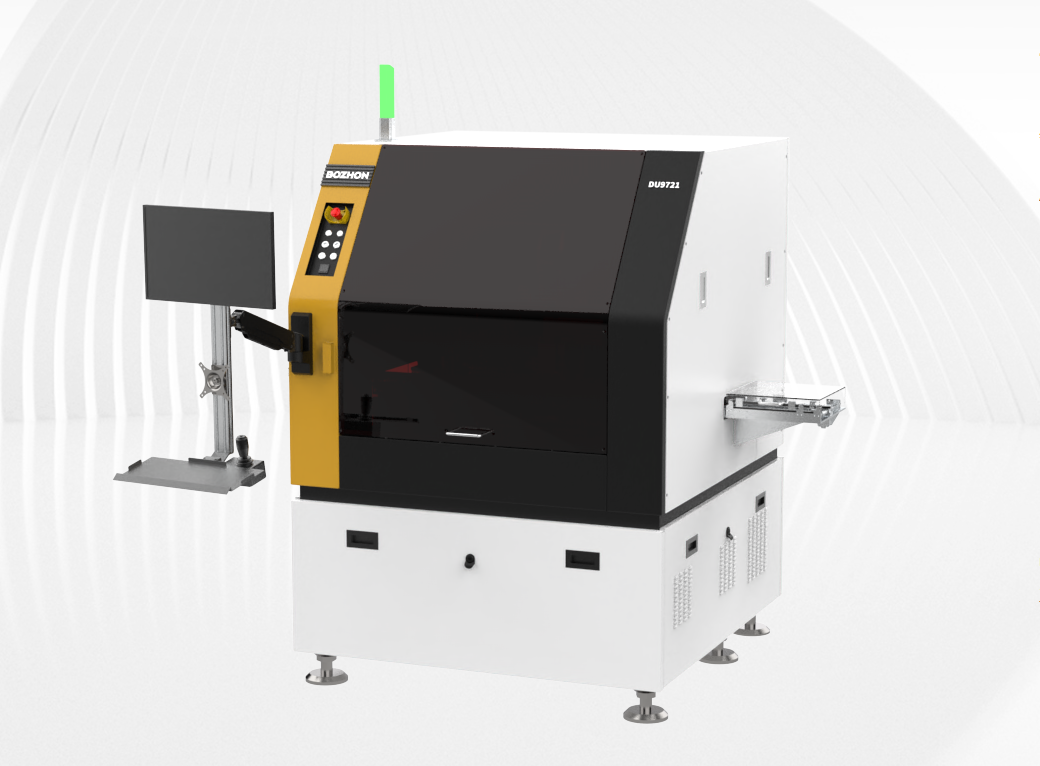

· FastStar series die attach machines ·

FastStar series die attach machines

The FastStar series die attach machines are high-speed and high-precision devices designed for multi-chip packaging, with a chip mounting accuracy of up to ±7μm@3σ. Featuring an open architecture and modular design, they can provide the capability of customized solutions with ultimate efficiency according to specific needs. They can be compatible with wafers up to 12 inches at the maximum, and meet packaging processes such as die bonding, System in Package (SiP), and UV curing.

✅ High Precision

- Meets micron-level chip mounting accuracy and enables ultimate chip mounting efficiency.

✅ High Flexibility

- It supports multiple feeding forms.

- It supports packaging processes such as Die attach, SiP (System in Package), and UV (Ultraviolet) curing.

✅ Multifunctionality

- It is compatible with die bonding, flip-chip bonding, and multi-chip packaging.

✅ Modularity

- It is compatible with the development requirements of different product categories.

- It can be flexibly customized according to customers' demands.

We sincerely invite you to visit the booth of Bozhon Semiconductor at SEMICON China 2025.

Let's jointly explore the cutting-edge technologies and innovative applications in semiconductor packaging and testing.

We are looking forward to meeting you in Shanghai.

Join hands in this grand event and embark on a new journey in the “semiconductor - core” era!

Bozhon Semiconductor Booth Number: N5.5425